Dental diamond burs deliver precision and efficiency for every procedure. Learn how to choose, use, and maintain dental diamond burs for optimal results.

The right tool can make a procedure feel effortless. A high-quality bur glides smoothly, while a poorly made one leads to frustrating chatter and compromised results. That difference in performance and control is what separates a difficult procedure from a seamless one. The key lies in the quality of your dental diamond burs. A superior bur is defined by its cutting efficiency and longevity, featuring strong, uniformly bonded diamond particles for a smooth cut without excess heat. When you’re ready to feel that difference, explore SurgiMac’s premium selection, designed with the same reliability you trust from our MacSuture line.

Key Takeaways

-

Master Bur Selection for Procedural Success: Choose the right bur by matching its shape and grit to the specific task. Use coarse-grit burs for efficient bulk reduction and fine-grit burs for smooth finishing, ensuring you have the precise tool for every step from crown preps to cosmetic refinements.

-

Proper Technique Extends Bur Life and Protects Patients: Use a light touch with adequate water cooling to prevent heat damage and premature wear. A consistent cleaning, sterilization, and storage routine keeps your burs in peak condition, ensuring they perform safely and effectively.

-

Invest in Quality for a Better Return: High-quality burs from a trusted supplier like SurgiMac deliver superior performance and durability. While the initial cost may be higher, their longevity and efficiency result in a lower cost-per-use and more predictable clinical outcomes.

What is a Diamond Dental Bur?

What is a Diamond Dental Bur?

If you've ever prepped a crown or refined a restoration, you know how crucial the right bur is. Diamond dental burs are the workhorses of cosmetic and restorative dentistry. Think of them as highly specialized tools with tiny diamond particles bonded to their surface. These particles allow you to precisely cut and grind the hardest tissues in the mouth, like tooth enamel and ceramics, with incredible efficiency. They are essential for achieving the clean margins and smooth surfaces that define high-quality dental work. Understanding how they work and what makes them different from other burs is the first step to mastering their use in your practice.

How Do Diamond Particles Cut So Effectively?

Unlike carbide burs that cut with sharp blades, diamond burs work by grinding. The technology is straightforward but effective: thousands of fine diamond particles are electroplated onto the bur's head. As the bur rotates at high speed, these particles act as an abrasive, efficiently removing hard tissue. This grinding action is perfect for creating smooth, precise margins on enamel and porcelain. It’s less effective on softer materials or metals, where a carbide bur’s slicing action is more suitable. For any procedure involving hard tissues, diamond burs are your go-to for control and a refined finish.

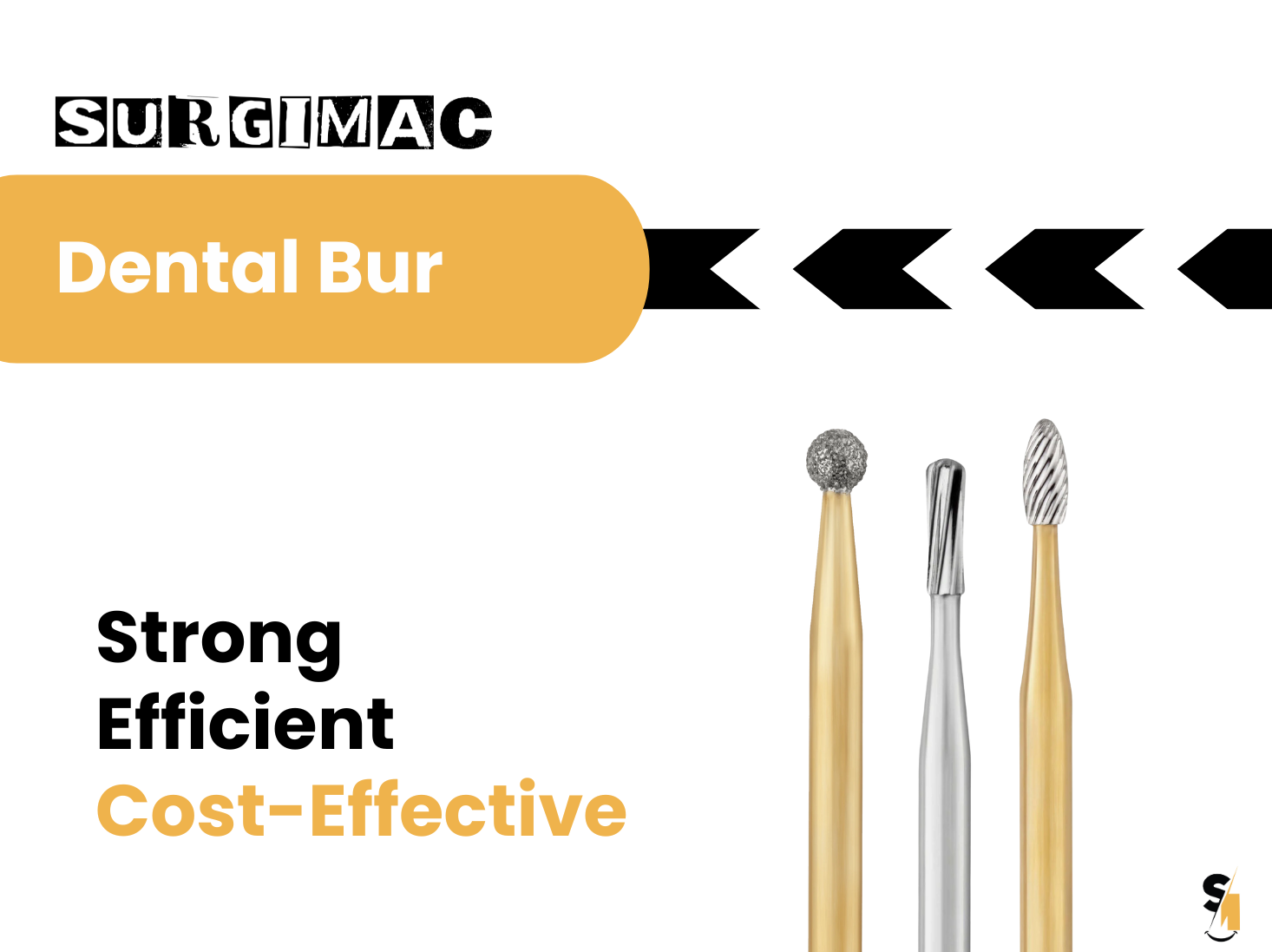

Breaking Down the Parts of a Diamond Bur

Every diamond bur has two main parts: the shank and the head. The shank is the long part that fits into your handpiece. You’ll typically see Friction Grip (FG) shanks for high-speed handpieces and Right Angle (RA) shanks for low-speed contra-angles. The head is the working end, coated in diamond particles. It comes in a huge variety of shapes—like round, pear, flame, and tapered—each designed for a specific task. A round bur is great for initial entry, while a tapered bur helps create the perfect crown prep. Knowing your shapes is key to procedural efficiency.

The Head, Neck, and Shank

To get the most out of your bur, it helps to understand its basic anatomy. Every diamond bur consists of a head, a neck, and a shank. The head is the working end, coated in diamond particles that perform the cutting and grinding. As a beginner's guide explains, the variety of head shapes is vast—from round and pear to flame and tapered—with each one engineered for a specific clinical task. The shank is the long, smooth part that inserts into your handpiece, providing the connection to the power source. Connecting these two is the neck, which provides clearance and visibility during procedures. The balance and construction of these parts are crucial for performance, much like the precision-engineered instruments in our Pro Series line.

Understanding Shank Types

Not all shanks are created equal, and matching the right one to your handpiece is essential for safety and efficiency. The most common type you'll use is the Friction Grip (FG) shank, designed for high-speed handpieces used in procedures like crown preparations and enameloplasty. For low-speed contra-angle handpieces, you’ll need a Right Angle (RA) shank, which is ideal for finishing, polishing, and caries removal. Using the wrong shank can damage your handpiece and compromise the procedure. Always confirm compatibility before starting, ensuring you have the correct bur for the job at hand.

The Handpiece (HP) Shank

A third, less common but equally important type is the Handpiece (HP) shank. These are longer than FG or RA shanks and are designed specifically for the straight attachment on a low-speed handpiece. You'll typically use HP shanks for tasks performed outside the mouth, such as adjusting dentures, trimming acrylics, or polishing provisional restorations in the lab. Their extended length provides the necessary reach and control for these applications. Understanding the distinction between FG, RA, and HP shanks allows you to select the right tool from your dental supply inventory, ensuring every procedure is performed with the appropriate equipment.

How Do Diamond Burs Compare to Carbide and Ceramic?

Choosing the right bur material is as important as choosing the right shape. Diamond burs excel at grinding brittle materials like enamel and porcelain. Their abrasive nature provides a smooth, controlled cut. Carbide burs, on the other hand, have flutes that slice through material, making them ideal for cutting metal and softer tooth structures like dentin. Ceramic burs are also an option for specific tasks like soft decay removal. Stocking a variety of burs ensures you’re prepared for any situation, just like having a full range of our MacSuture products on hand for closures.

Diamond vs. Carbide Burs

The primary difference between diamond and carbide burs lies in their method of action. Diamond burs are grinders; their abrasive surface is designed to wear away hard, brittle materials with exceptional control. This makes them the go-to instrument for precisely cutting through enamel and porcelain, allowing you to create smooth finishes for crown preparations and refine margins flawlessly. Carbide burs, in contrast, operate like chisels. They have sharp flutes that slice or chip away at the material, which is highly effective for removing old metal restorations, sectioning teeth, or quickly excavating softer dentin. It’s not about which is better, but which is right for the job—a well-stocked operatory needs both to handle the full spectrum of dental materials.

Diamond vs. Steel Burs

While steel burs have a history in dentistry, their modern application is quite specialized. They are significantly softer and less durable than their diamond or carbide counterparts, rendering them unsuitable for cutting hard tooth structures like enamel. You'll typically find steel burs used at lower speeds for tasks like finishing and polishing restorations or for very gentle caries removal in soft, decayed dentin. For any procedure requiring efficient shaping or reduction of hard tissues, diamond burs offer vastly superior durability and cutting power. Consider steel burs a delicate finishing tool in your arsenal, not the instrument for heavy-duty preparation work.

Diamond vs. Ceramic Burs

Ceramic burs have found a valuable niche, especially for conservative caries removal. Their biocompatibility and ability to selectively remove decayed dentin while preserving healthier tooth structure make them an excellent choice for specific clinical situations. However, when you’re faced with cutting extremely hard materials like enamel, zirconia, or porcelain, diamond burs are more effective and significantly less prone to fracturing under pressure. While a ceramic bur is a fantastic tool for careful excavation, the unmatched strength and versatility of diamond burs establish them as the essential workhorse for the majority of restorative and cosmetic procedures. Having a complete selection of burs and diamonds ensures you’re prepared for any clinical challenge.

Selecting the Perfect Diamond Bur for Your Procedure

Selecting the right diamond bur is less about finding a single do-it-all tool and more about building a versatile toolkit. The success of any procedure, from a simple restoration to complex crown preparation, depends on having the perfect instrument for each specific step. The shape of the bur dictates its function, the grit size determines the finish, and specialized burs can make challenging tasks feel routine. Understanding these key differences will help you work more efficiently, achieve better clinical outcomes, and improve the patient experience. Let’s break down how to match the right bur to the right job.

Matching Bur Shapes to Clinical Applications

The shape of a diamond bur is its most defining feature, directly influencing how it cuts and contours tooth structure. Round burs are perfect for initial entry and creating access points, while flat-end tapered burs are your go-to for crown preparations, creating smooth walls and defined margins. Pear-shaped burs are excellent for excavation and creating undercuts in restorative work. Each shape is designed for a specific function, allowing you to perform precise actions with confidence. Familiarizing yourself with the applications of each bur shape helps you select the right tool instinctively, saving time and effort.

Barrel Burs

When you need to remove a significant amount of tooth structure or smooth down large, flat surfaces, the barrel bur is an indispensable tool. Barrel burs are specifically designed for removing large amounts of material and smoothing surfaces, making them highly effective for occlusal reduction during crown preparations. Their cylindrical shape allows for uniform reduction, ensuring you create a stable and even foundation for restorations. This efficiency not only saves chair time but also contributes to a more predictable outcome for your restorative work. Having a reliable set of barrel burs in your armamentarium is fundamental for restorative dentistry, and you can find a full range in our collection of dental burs and diamonds.

Football Burs

For the delicate art of occlusal adjustment, the football-shaped bur is unmatched. As their name suggests, football burs are best for adjusting the biting surfaces of teeth, allowing you to precisely sculpt cusps and fossae. The unique, rounded contour of the bur head mimics the natural anatomy of posterior teeth, making it perfect for refining composite restorations or adjusting the occlusion on crowns. This shape enables you to create smooth, flowing surfaces that are both functional and aesthetically pleasing, ensuring the final restoration integrates seamlessly with the patient's dentition and promotes proper function.

Wheel Burs

When it comes to anterior aesthetics, precision is everything, and the wheel bur is designed for just that. Wheel burs are ideal for shaping the biting edges of front teeth, giving you complete control over incisal length and contour. Whether you are perfecting the incisal edge of a veneer preparation or creating subtle anatomical details on a composite restoration, the wheel bur’s design provides excellent visibility and access. Its shape is also useful for gross reduction on lingual surfaces, making it a versatile tool for a variety of anterior procedures where detailed shaping is required to achieve a beautiful, natural-looking smile.

Choosing the Right Grit: From Coarse to Superfine

Beyond shape, the grit size of the diamond particles determines the bur’s abrasiveness and the resulting surface finish. Diamond burs use a standardized color-coding system to make identification simple. Burs with black or green bands are coarse or super-coarse, designed for rapid, bulk removal of tooth structure or old restorative materials. Blue bands indicate a medium grit, which is a versatile choice for standard preparation work. For finishing and polishing, you’ll want to reach for burs with red (fine), yellow (superfine), or white (ultrafine) bands. Using a progression of grits allows you to efficiently shape a preparation and then leave it with a smooth, polished surface ready for bonding.

Decoding the Grit Color-Coding System

To keep things simple and efficient chairside, diamond burs follow a universal color-coding system based on the ISO classification. This system allows you to identify a bur’s grit size with just a quick glance, eliminating guesswork and saving valuable time during procedures. The color band on the shank of the bur tells you everything you need to know about its abrasiveness, ranging from super coarse for aggressive reduction to ultrafine for high-gloss polishing. Understanding this simple visual language is fundamental to selecting the right instrument for each stage of a procedure, ensuring you move seamlessly from bulk removal to final finishing without interrupting your workflow.

Aggressive Reduction: Super Coarse (Black) and Coarse (Green)

When you need to remove a significant amount of tooth structure or an old restoration quickly, reach for a bur with a black (super coarse) or green (coarse) band. These burs are engineered for maximum cutting efficiency and are your go-to for tasks like crown preparations, occlusal reduction, or cutting through old amalgam or ceramic crowns. Their large diamond particles remove material rapidly, but they also leave a rough surface. Think of them as the heavy-duty tools in your kit, perfect for the initial, aggressive stages of a procedure before you move on to more refined instruments for shaping and smoothing.

Universal Use: Medium (Blue)

The blue-banded bur is arguably the most versatile and frequently used diamond bur in any dental practice. With its medium grit, it strikes the perfect balance between efficient cutting and a relatively smooth surface finish. This makes it an excellent all-purpose tool for a wide range of applications, including universal tooth preparation, shaping, and contouring. Whether you're refining a crown prep after initial bulk reduction or working on a composite restoration, the blue-banded bur provides the control and consistency you need for everyday procedures. It’s the reliable workhorse that you’ll find yourself reaching for time and time again.

Finishing and Polishing: Fine (Red), Extra Fine (Yellow), and Ultra Fine (White)

For the final stages of a procedure where a smooth, refined surface is critical, you’ll need burs with finer grits. Red-banded (fine) burs are ideal for finishing preparations and restorations, removing minor imperfections left by medium-grit burs. For an even smoother surface, especially on composites or ceramics, yellow-banded (extra fine) burs are the next step. Finally, the white-banded (ultra fine) burs are used for the final polish, creating a high-luster finish that resists plaque accumulation and staining. Using this progression ensures your restorations not only look great but also have optimal marginal integrity and longevity.

When Do You Need a Specialty Diamond Bur?

While standard burs cover most of your daily needs, certain situations call for a specialized tool. For instance, some premium diamond burs are specifically designed for preparing vital teeth, offering smoother cutting action with less vibration to enhance patient comfort. Other specialized burs are engineered to cut through modern materials like zirconia or lithium disilicate without chipping or generating excessive heat. Having a few of these specialty burs on hand can turn a potentially difficult procedure into a predictable one. They are an investment in efficiency and precision, especially as cosmetic and restorative dentistry continues to evolve with new materials and techniques.

Find Your Perfect Bur in the SurgiMac Collection

The effectiveness of any bur comes down to its quality. Premium diamond burs, like those in SurgiMac’s collection of burs and diamonds, feature a dense, uniform coating of diamond particles. This ensures they cut efficiently and wear evenly, giving you a longer service life. They are ideal for working on hard surfaces like enamel and porcelain, delivering clean margins and smooth finishes every time. Having a reliable supplier for all your clinical needs, from high-performance burs to essential closure products like the MacSuture line, helps streamline your inventory management and ensures you always have trusted tools ready for any procedure.

Navigating the Wide Variety of Shapes and Sizes

When it comes to dental burs, understanding the variety of shapes and sizes is crucial for achieving optimal results. A bur's shape is its most defining feature, directly influencing how it cuts and contours tooth structure. For instance, round burs are perfect for initial entry and creating access points, while flat-end tapered burs are ideal for crown preparations, creating smooth walls and defined margins. Pear-shaped burs excel in excavation and creating undercuts in restorative work. Each shape is designed for a specific function, and having the right assortment of diamond burs enables you to perform precise actions with confidence.

The grit size of the diamond particles also plays a significant role in performance. Burs with black or green bands are coarse or super-coarse, designed for rapid, bulk removal of tooth structure or old restorative materials. In contrast, burs with red (fine), yellow (superfine), or white (ultrafine) bands are used for finishing and polishing, ensuring a smooth surface ready for bonding. By familiarizing yourself with the applications of each bur shape and grit, you can instinctively select the right tool for each task, ultimately saving time and enhancing the quality of your dental work.

A Clinician's Checklist for Selecting Quality Diamond Burs

Choosing the right diamond bur isn’t just about finding the right shape or grit; it’s about investing in an instrument that delivers consistent, predictable results for your patients and your practice. A high-quality bur can make procedures smoother, faster, and more comfortable, while a poorly made one can lead to frustration, wasted time, and compromised clinical outcomes. Understanding the key markers of quality will help you confidently select burs that perform reliably every time. Think of it as choosing the right tool for a precision craft—because that’s exactly what dentistry is.

What Makes a Diamond Bur Superior?

A top-tier diamond bur is defined by its cutting efficiency and longevity. The best burs are made with strong, natural diamond particles that are uniformly distributed and securely bonded to the shank. This ensures a smooth, consistent cut without creating excessive heat or vibration. When the diamond powder stays attached, the bur doesn't wear out quickly, giving you more uses and better value. A superior bur feels balanced in your handpiece and removes material predictably, allowing you to work with confidence. When you’re ready to see the difference, you can explore SurgiMac’s premium selection of burs and diamonds designed for optimal performance.

How to Interpret ISO Bur Classifications

The ISO classification system is your guide to ensuring consistency and safety in your bur selection. These numbers aren't just arbitrary codes; they provide a universal language for identifying a bur's material, shank type, head shape, and grit size. Understanding these classifications helps you select the exact tool you need for a specific procedure, regardless of the brand. The quality of a diamond bur greatly affects how well a dental procedure goes and the final look of the dental work. Relying on ISO standards means you can trust that your bur meets global benchmarks for quality and design, ensuring predictable performance from one bur to the next.

How to Spot the Signs of Quality and Durability

Beyond ISO numbers, you can often spot quality with a simple visual inspection. A well-made bur has a perfectly concentric, stainless steel shank that won’t wobble or vibrate in the handpiece. A poor shaft can cause excessive shaking, making precise work difficult and potentially damaging the tooth or your equipment. Look for an even coating of diamond particles with no bald spots. The same commitment to precision manufacturing that goes into SurgiMac’s other trusted supplies, like our MacSuture line, is essential for dental burs. A durable, well-crafted bur not only performs better but also ensures the safety of both you and your patient.

Is a More Expensive Bur Always Better?

While it can be tempting to opt for lower-priced burs, it’s important to consider the total value. High-quality burs may have a higher initial cost, but they often deliver a lower cost-per-use. Because they are more durable and efficient, they last longer and help you complete procedures more quickly, saving you money and chair time in the long run. Investing in performance means fewer burs discarded after a single use and more predictable outcomes. This approach to managing practice expenses focuses on long-term value over short-term savings, ultimately benefiting your workflow and your bottom line.

Using Diamond Burs in Key Clinical Procedures

Once you’ve selected the right diamond bur, it’s time to put it to work. The true test of a quality bur is its performance during critical procedures where precision is everything. Using the correct bur not only improves the quality of your work but also enhances efficiency and patient comfort. From preparing a tooth for a crown to refining a delicate cosmetic restoration, diamond burs are indispensable tools in your daily practice. Let’s look at how these instruments perform in some of the most common dental applications.

Perfecting Crown and Bridge Prep with Diamond Burs

When it comes to crown and bridge work, success starts with a perfect preparation. Diamond burs are essential tools used to shape teeth precisely for crowns and bridges, ensuring a flawless fit and long-lasting results. Using a coarse-grit bur allows for efficient bulk reduction of enamel, while a finer-grit bur helps create smooth, well-defined margins. Tapered and chamfer burs are particularly useful for establishing the ideal axial wall convergence and margin design. A clean, accurate prep prevents open margins, reduces the risk of secondary caries, and provides the best foundation for your crowns and bands.

Using Diamond Burs for Precision in Cosmetic Dentistry

In cosmetic dentistry, the details make all the difference. Diamond burs are celebrated for their ability to cut quickly and precisely, which is vital for procedures like veneers and composite bonding. Their efficiency creates less heat, which is better for the tooth and leads to a more comfortable patient experience. Fine and superfine grit burs are your go-to instruments for contouring, finishing, and polishing restorations to a natural, high-gloss luster. This level of precision allows you to create seamless margins and lifelike anatomy, giving your patients the beautiful, confident smiles they expect.

Streamlining Endodontic Access and Shaping

A successful root canal treatment begins with a well-designed access cavity. Diamond burs are frequently used to create clear entry points for endodontic procedures, allowing you to locate and instrument canals effectively. Round or tapered diamond burs can efficiently cut through enamel and dentin, including tough materials like porcelain or metal restorations. Achieving straight-line access is critical for preventing procedural errors like ledging or perforation. For such a delicate procedure, you need tools you can count on, from your burs to your closure materials like our reliable MacSuture sutures.

Refining Restorative Techniques with Diamond Burs

For restorative work, the final finish is just as important as the initial prep. Diamond burs are ideal for polishing and working on hard surfaces like porcelain or composite materials. After placing a restoration, fine and superfine diamond burs are used to smooth the surface, remove any excess material, and create a seamless transition between the restoration and the natural tooth. This meticulous finishing process not only improves the esthetics but also contributes to the longevity of the restoration by creating a surface that is more resistant to staining and plaque accumulation.

Applications in Orthodontics

In orthodontics, where precision is everything, diamond burs are indispensable for several key procedures. They are the go-to tool for interproximal reduction (IPR), where a specific amount of enamel is removed to create space for tooth movement. Fine-grit diamond burs allow for controlled and predictable enamel stripping, ensuring patient safety and optimal outcomes. Another critical application is the removal of residual bonding adhesive after debonding brackets. Using a fine-finishing diamond bur ensures that all composite is removed without scarring or damaging the underlying enamel, leaving a smooth, polished surface. These delicate tasks demand tools that offer maximum control and reliability, which is why selecting high-quality dental burs is a fundamental part of successful orthodontic finishing.

Technique Tips for Using Diamond Burs Effectively

Getting the most out of your diamond burs isn’t just about choosing the right shape or grit; it’s about technique. Mastering how you use these essential tools can make a world of difference in your clinical outcomes, patient comfort, and even the lifespan of your burs. From finding the perfect balance of speed and pressure to managing heat, a few key adjustments to your workflow can help you work more efficiently and with greater precision. Let’s walk through some pro tips to help you handle your diamond burs with confidence.

Finding the Optimal Speed and Pressure

Think of your handpiece and bur as a high-performance instrument—it works best with a skilled, gentle touch. Applying the right speed and light pressure is crucial for optimal performance and longevity. Pushing too hard or running the bur too fast can generate excess heat, cause premature wear, and lead to chatter, which compromises the quality of your prep. Instead, let the bur do the work. Use a light, consistent touch and follow the manufacturer's recommended RPM settings for the specific bur you’re using. This approach not only preserves the tooth structure but also extends the life of your dental equipment, saving you time and money.

Why Cooling and Lubrication Matter

Friction creates heat, and in dentistry, excess heat is the enemy of healthy pulp. That’s why effective cooling is non-negotiable when working with diamond burs. Utilizing a steady water spray or air-water coolant is essential to prevent overheating the tooth and the bur during procedures. An adequate stream of water does more than just keep temperatures down; it also flushes away debris from the cutting surface. This keeps the bur’s diamond particles from getting clogged, which maintains cutting efficiency and gives you a much clearer view of the operating field. Proper cooling is a simple step that directly contributes to better clinical outcomes and patient safety.

Troubleshooting Common Issues with Diamond Burs

Even the best diamond burs have a limited lifespan. It's a simple fact that diamond burs experience significant wear after multiple uses. As they become worn, their cutting efficiency drops, which can lead to suboptimal results and more chair time. A dull bur forces you to apply more pressure, increasing friction, heat, and the risk of damaging the tooth. Get into the habit of regularly inspecting your burs for signs of wear, like missing diamond particles or a visibly smooth surface. Starting each procedure with a sharp, effective bur is key. Investing in high-quality tools, like SurgiMac’s line of burs and diamonds, ensures you get reliable performance and durability.

Techniques for Managing Heat and Protecting Tooth Structure

Managing thermal output is one of the most critical aspects of tooth preparation. Using diamond burs on hard materials like enamel or ceramic can lead to excessive wear, making them ineffective and potentially harmful to the tooth due to heat generation. This heat can cause more than just pulpal irritation; it can create micro-fractures in the surrounding tooth structure, weakening the final restoration. To prevent this, always use a sharp bur, ensure a powerful and well-aimed stream of coolant, and adopt a "brushing" or intermittent cutting motion. This technique allows the tooth and bur a moment to cool between passes, protecting the tooth’s integrity and ensuring a more precise, controlled preparation.

How to Care for and Maintain Your Diamond Burs

Investing in high-quality diamond burs is the first step, but getting the most out of that investment comes down to proper care and maintenance. A well-maintained bur not only lasts longer, saving you money, but it also performs more efficiently and safely. Think of it as protecting your tools to protect your patients and your work. By following a few simple protocols for cleaning, storage, and use, you can ensure your burs remain in peak condition for every procedure. This consistent care routine is just as important as using premium supplies for other aspects of your practice, from cements to sutures.

Step-by-Step Cleaning and Sterilization Protocols

After each use, it’s essential to thoroughly clean your burs to remove any bioburden and debris. Leftover material can clog the diamond particles, drastically reducing cutting efficiency and making sterilization less effective. Start by manually scrubbing the bur with a dedicated brush, then place it in an ultrasonic cleaner for a deep clean. Once the bur is visibly clean, you must sterilize it according to the manufacturer’s instructions, which typically involves autoclaving. This critical step prevents cross-contamination and ensures you’re always working with a safe, sterile instrument for every patient.

Initial Rinsing After Use

The first and most crucial step in bur maintenance happens the moment you finish a procedure. Immediately rinsing the bur under cool, running water is a simple habit that pays off in the long run. This initial rinse washes away gross debris like blood, saliva, and tissue before it has a chance to dry and harden onto the diamond particles. Think of it as the first line of defense in your infection control process. When debris is allowed to set, it can be much more difficult to remove later, effectively clogging the abrasive surface and reducing the bur's cutting efficiency. A quick rinse ensures that subsequent cleaning and sterilization steps are far more effective.

Gentle Brushing Techniques

After the initial rinse, a gentle but thorough brushing is necessary to dislodge any remaining adherent debris. Use a soft-bristled brush, such as a brass or nylon bur brush, to carefully clean the head of the bur. It’s important to use a light touch; scrubbing too aggressively can strip the diamond particles from the shank, rendering the bur useless. The goal is to meticulously clean between the diamond grits without causing damage. This manual cleaning step is critical for preparing your dental instruments for the ultrasonic bath, ensuring that no organic material is left to interfere with the final sterilization process.

Best Practices for Storing Your Diamond Burs

How you store your burs matters more than you might think. Tossing them into a drawer is a recipe for damage. The delicate diamond coating can get chipped or worn down from contact with other instruments. The best practice is to keep your burs in a clean, dry, and dedicated bur block or holder. This not only protects them from physical damage but also keeps them organized and easily accessible, which can streamline your workflow during procedures. A good storage system prevents contamination and ensures that when you reach for a bur, it’s in perfect condition and ready to perform.

How to Extend the Life of Your Burs

The way you use a bur directly impacts its lifespan. To make your diamond burs last, always use the recommended speed (RPM) and apply light, consistent pressure. Pushing too hard or running the handpiece too fast generates excess heat, which can quickly wear down the diamond particles and even cause thermal damage to the tooth. Instead of force, use a gentle, intermittent "painting" motion. Paired with an adequate stream of water for cooling and lubrication, this technique allows the bur to cut efficiently without being overworked. This approach not only preserves the bur but also leads to cleaner preparations and a better experience for your patient.

When Should You Replace Your Diamond Bur?

Even the best burs don't last forever. Using a dull bur is inefficient, generates more heat, and can compromise the quality of your work. As a general rule, many clinicians suggest replacing a diamond bur after preparing about five teeth. However, you should also rely on visual and tactile cues. If a bur looks dull, has visible bald spots in the diamond coating, or feels like it’s sliding over the tooth instead of cutting, it’s time for a replacement. Just as you rely on fresh, sterile MacSuture sutures for predictable healing, you need sharp, effective burs for precise preparations. Keeping a ready supply of high-quality burs and diamonds from a trusted source like SurgiMac ensures you never have to compromise on performance.

Working Safely and Efficiently with Diamond Burs

Using the right tools is about more than just getting the job done—it’s about protecting your patients, your equipment, and yourself. When you prioritize safety and efficiency, you create a smoother workflow, reduce chair time, and deliver consistently excellent results that build patient trust. A high-quality diamond bur isn’t just a cutting instrument; it’s a key component of your commitment to clinical excellence. By focusing on a few core principles, you can make sure every procedure is as safe and effective as possible.

This means paying close attention to the quality of your burs, ensuring they are perfectly compatible with your handpieces, and mastering techniques that give you precise control. It’s about understanding how factors like vibration and surface finishing impact the final outcome. At SurgiMac, we believe that superior tools are fundamental to superior care. We ensure all our products, from our premium burs and diamonds to our trusted MacSuture line, meet the highest standards of quality and safety. Let’s walk through the key practices that will help you get the most out of your diamond burs while keeping safety at the forefront.

Essential Safety Protocols for Bur Usage

The quality of your diamond bur directly impacts the safety and success of a procedure. A well-made bur cuts cleanly and efficiently, minimizing heat generation and reducing the risk of thermal damage to the pulp. In contrast, a low-quality or worn-out bur requires more pressure, which can lead to microfractures in the tooth structure and cause unnecessary discomfort for your patient. Choosing a premium bur is a fundamental safety measure. It ensures predictable, precise cutting, which protects the surrounding soft tissues from accidental nicks and abrasions. Think of it as an investment in both the quality of your work and the well-being of your patients.

How to Ensure Handpiece and Bur Compatibility

One of the simplest yet most critical safety checks is ensuring your bur is compatible with your handpiece. Diamond burs come with different shanks designed to fit specific handpieces, most commonly FG (Friction Grip) for high-speed turbines, RA (Right Angle) for latch-type contra-angle handpieces, and HP (Handpiece) for straight handpieces. Using the wrong shank can damage your handpiece’s chucking mechanism and, more importantly, create a serious safety risk if the bur comes loose during a procedure. Always confirm compatibility before you begin. This quick step prevents equipment damage and ensures the bur is securely seated, providing stable and safe operation every time.

Tips for Minimizing Vibration and Improving Control

Have you ever worked with a bur that seems to "chatter" against the tooth? That excessive vibration is more than just an annoyance—it compromises your control and precision. High-quality diamond burs are manufactured to be perfectly concentric, meaning they spin smoothly without wobbling. This stability minimizes vibration, which reduces hand fatigue and allows for greater tactile sensitivity. When you can feel the bur working smoothly, you can create sharper margins and more refined preparations. Less vibration also means a more comfortable experience for the patient. This is where the quality of the bur’s shaft and diamond bonding truly makes a difference in your daily practice.

Techniques for Achieving a Perfect Surface Finish

Achieving a perfectly smooth surface is essential for the longevity of any restoration. Diamond burs are your go-to tools for finishing and polishing hard materials like enamel and porcelain. The key is to work through a sequence of grits, moving from coarser burs for bulk reduction to finer ones for smoothing. This methodical approach removes striations and creates a high-gloss finish that resists plaque accumulation and staining. Mastering your finishing technique with a light touch and adequate water spray not only improves the esthetics of your work but also contributes to better oral health for your patient.

Making a Smart Investment in Dental Diamond Burs

Choosing the right dental burs is more than just a routine supply order—it's an investment in your practice's efficiency, precision, and patient outcomes. Making smart choices means looking beyond the price tag to consider your specific procedural needs, the quality of the materials, and the reliability of your supplier. A well-stocked inventory of high-quality burs allows you to perform at your best without interruption, ensuring every procedure is smooth and predictable. By taking a strategic approach to purchasing, you can equip your practice with the tools you need to deliver exceptional care while also managing your budget effectively. Let's walk through how to make the best investment for your clinic.

How to Evaluate Your Practice's Needs

Before you place your next order, take a moment to assess what your practice truly needs. Think about the procedures you perform most frequently. Are you doing a lot of crown preparations, cosmetic veneers, or simple restorative work? The answer will guide your inventory decisions. For example, round, tapered, and flat-end burs are staples for many dentists, as each shape is designed for specific tasks that require precision. By creating a core list of your most-used bur shapes and grit sizes, you can avoid overstocking on items you rarely use. This focused approach ensures you always have the right tool on hand, streamlining your workflow and making every procedure more efficient.

Finding the Sweet Spot Between Quality and Price

It can be tempting to opt for lower-priced burs to cut costs, but this can be a shortsighted strategy. High-quality diamond burs are an investment that pays off in the long run. They are typically made with strong, natural diamond powder that adheres firmly to the shank, ensuring they cut efficiently and last longer. A superior bur provides consistent performance, which translates to faster procedures and greater patient comfort. In contrast, cheaper burs can wear out quickly, cut inconsistently, and even increase the risk of iatrogenic damage. When you choose quality, you're investing in your practice's reputation for excellent, precise dental work.

Why Choosing a Trusted Supplier Matters

Your supplier is your partner in providing excellent patient care, so it’s important to choose one you can count on. When looking for a source for your burs, seek out a company with a solid reputation, positive customer reviews, and a professional, easy-to-use website. A great supplier offers a wide variety of dental equipment and supplies, making it simple to get everything you need in one place. Responsive and helpful customer service is also key—you want a team that can answer your questions and resolve any issues quickly. Building a relationship with a reliable supplier simplifies your procurement process and gives you confidence in the products you use every day.

The SurgiMac Promise: Quality, Warranty, and Support

Investing in high-quality burs is essential for providing safe and precise dental care, and that investment is protected when you choose a supplier that stands behind its products. At SurgiMac, we are committed to providing premium tools backed by excellent customer support and a reliable warranty. We want you to feel confident every time you use our products, from our advanced burs and diamonds to our trusted MacSuture line. When you partner with us, you’re not just buying supplies; you’re gaining a team dedicated to supporting your practice’s success. We ensure you have the dependable, high-performance tools you need to deliver outstanding results for your patients.

Frequently Asked Questions

1. What's the simplest way to remember when to use a diamond bur versus a carbide bur?

Think of it this way: diamonds grind, and carbides slice. You should reach for a diamond bur when working on hard, brittle surfaces like tooth enamel or porcelain and need a smooth, refined finish. A carbide bur is your best choice when cutting through softer materials like dentin or slicing through metal restorations where a bladed instrument is more effective.

2. If I'm just starting my practice, what are the absolute must-have diamond bur shapes?

To build a versatile starter kit, focus on the workhorses that cover the majority of your procedures. You'll want a solid selection of round burs for initial entry, flat-end tapered burs for creating precise crown preparations, and a few flame or football-shaped burs for finishing and contouring. This core group will equip you to handle most restorative and cosmetic tasks with confidence.

3. How can I tell if my diamond bur is worn out and needs to be replaced?

You’ll likely feel the difference before you see it. A worn-out bur starts to feel like it’s sliding or “chattering” against the tooth instead of cutting smoothly. You may find yourself applying more pressure, which generates heat. If you inspect it and notice bald spots where the diamond particles have worn away, it’s definitely time for a replacement.

4. Can I damage a tooth by using the wrong grit size?

Yes, using the wrong grit can compromise your work. A grit that’s too coarse during finishing can leave deep scratches on the tooth or restoration, creating a surface prone to staining and plaque buildup. Conversely, using a fine-grit bur for bulk reduction is inefficient and can generate excess heat, risking pulp damage. Always match the grit to the specific task.

5. Why is a high-quality bur from a brand like SurgiMac a better long-term investment?

While the initial cost might be slightly higher, a premium bur pays for itself in performance and durability. High-quality burs, like those from SurgiMac, are made with uniformly bonded diamond particles on a perfectly concentric shank. This means they cut faster, last longer, and create less vibration—resulting in better precision and a more comfortable patient experience. Investing in reliable tools, from your burs to MacSuture sutures, ultimately saves time, reduces replacement costs, and enhances overall clinical outcomes.

Read More